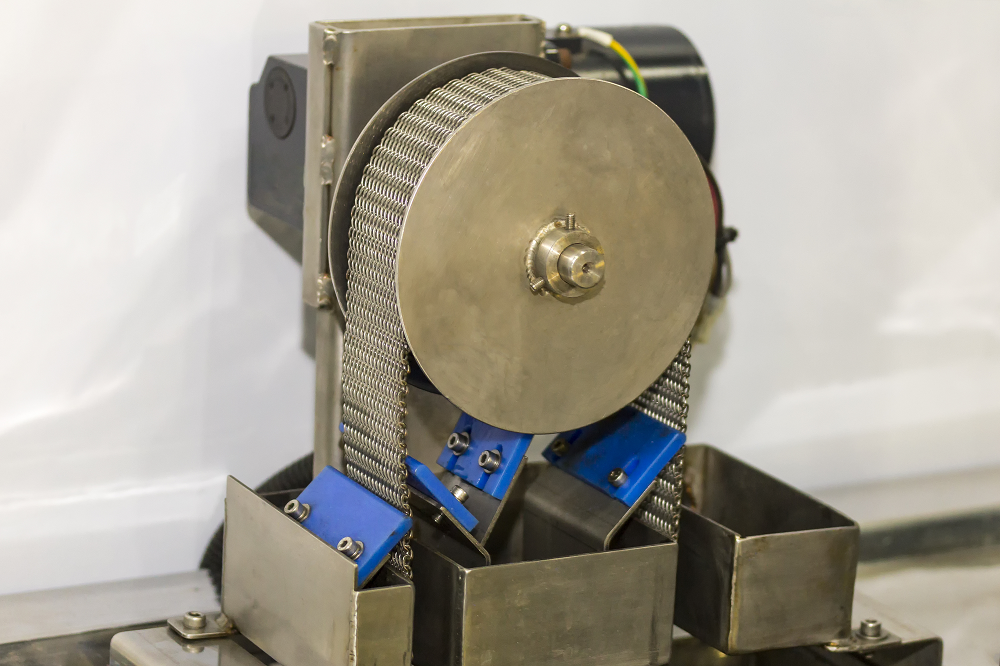

TRIM® Cutting Fluids’ 4 Biggest Breakthroughs

For 70 years, TRIM® coolants have redefined what metalworking fluids are capable of. Here are the biggest breakthroughs Master Fluid Solutions customers have achieved.

For 70 years, TRIM® coolants have redefined what metalworking fluids are capable of. Here are the biggest breakthroughs Master Fluid Solutions customers have achieved.

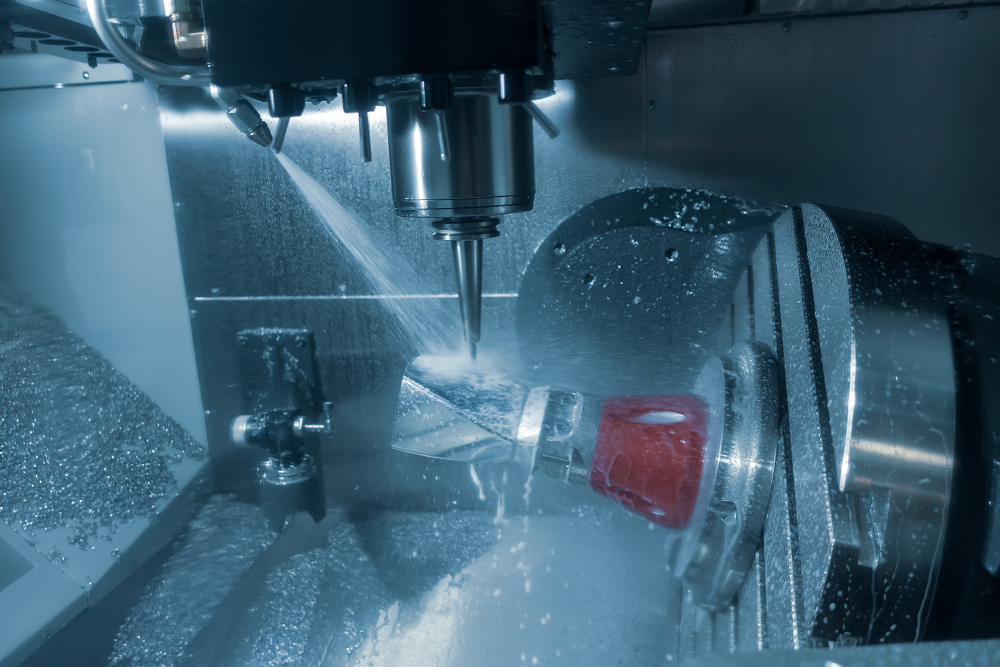

Coolant management is one of the best ways to minimize waste and save money, but it can also drastically improve productivity. Here’s how.

Drastically cutting costs and increasing productivity could be as simple as keeping your cutting fluid clean. Here’s how.

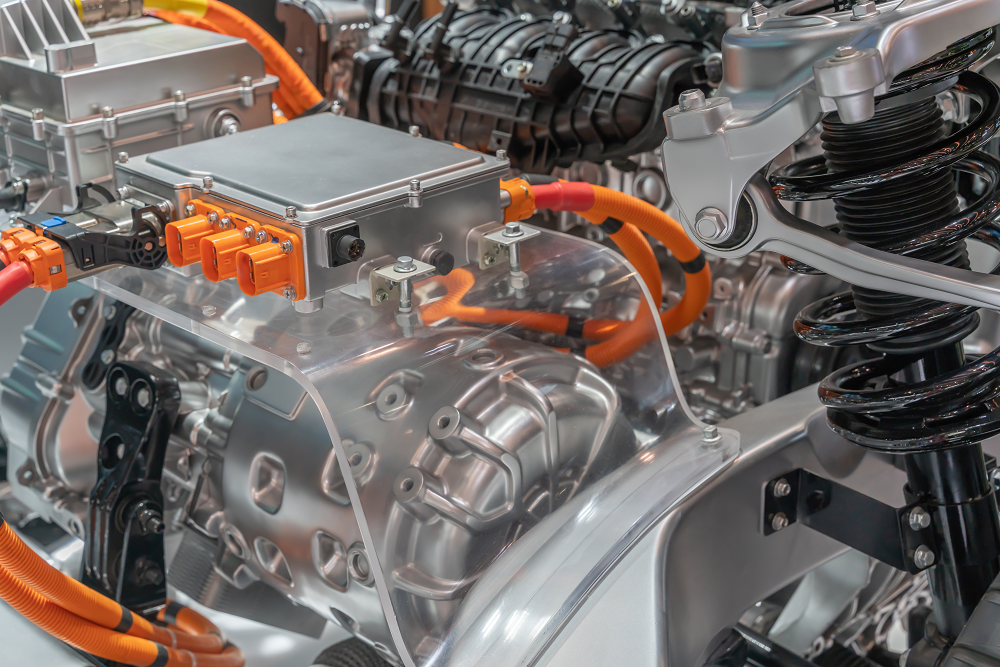

Electric vehicle manufacturing requires working with increasingly advanced metals. Here’s how the right cutting fluid can help incorporate them.

The global economy creates a number of challenges and opportunities for manufacturers. Here are three lessons Master Fluid Solutions® has learned along the way.

The manufacturing and metalworking industries are changing rapidly. Here’s what workers need to know to stay competitive in the market.

Properly maintained coolant can improve your operation. Here are four common coolant issues and how to address and overcome them.

A mixed-metal machining environment can be complicated to manage, but the right cutting fluid can control your supply costs and streamline your operation.

For more than 70 years, Master Fluid Solutions has pioneered sustainability and efficiency in the metalworking and manufacturing industries.

The progress made in mixed metals and composite machining have led to a number of new challenges. Here’s how advanced cutting fluids can help.