How to Optimize Coolant for Chilled Systems

Chilled systems require some special consideration. Here’s what to know to optimize coolant for chilled systems.

Chilled systems require some special consideration. Here’s what to know to optimize coolant for chilled systems.

The aerospace industry has stringent requirements for metalworking, including the coolants used. Learn how to identify if your coolant meets the high standards of aerospace.

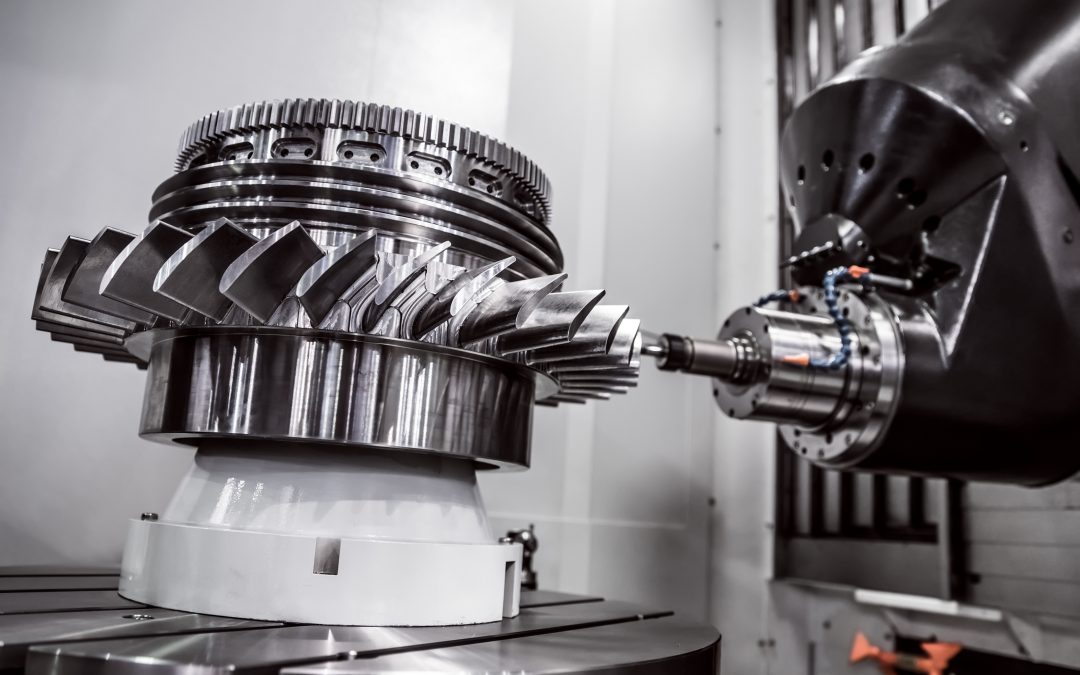

Innovative approaches to metalworking will help increase efficiency and help metalworking shops weather economic downturns. Here’s what the future of milling holds.

Biotech companies have taken the lead in the fight against COVID-19. Learn the surprising way metalworking is helping them in the battle.

Keeping our employees safe during COVID-19 is our top priority. In addition to following CDC and OSHA guidelines, we’re providing morale-boosting resources and programs. Here’s what we’re doing.

Shutdowns are a possibility for any metalworking shop during COVID-19 lockdowns. Here are steps to take to prepare your sump for a temporary shutdown.

With the recent rise of COVID-19, one of the precautionary measures that metalworking shops can take is to deep clean their machines. These are Master Fluid Solutions’ guidelines for protecting employees and scrubbing down machinery to remove potential contaminants.

The aerospace industry requires performance like no other – tighter tolerances, tougher regulations, and the need for every part to be perfect the first time, every time. HyperSol 888NXT was specially formulated to exceed standards without exceeding budgets. Learn about this new category of cutting-edge cutting fluid that helps aerospace take flight.

The right metalworking fluid is key to machine performance, and the less often you have to change it, the more you can keep costs down. Here are some best practices for extending the life of your metalworking fluid.