The Cutting Edge: Why Tramp Oil Removal Systems Increase Productivity and Protect the Bottom Line

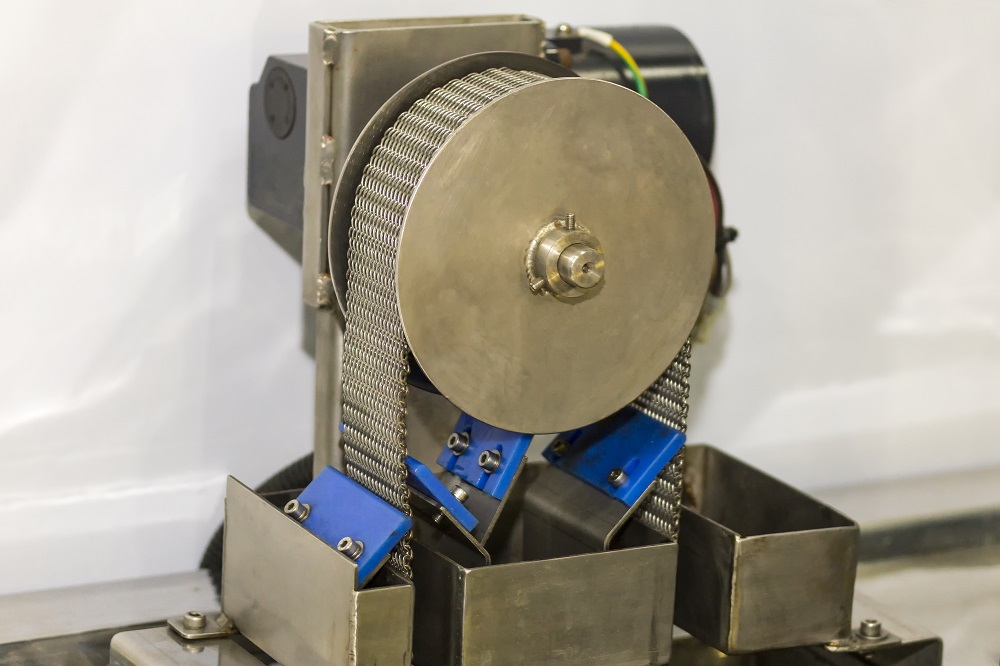

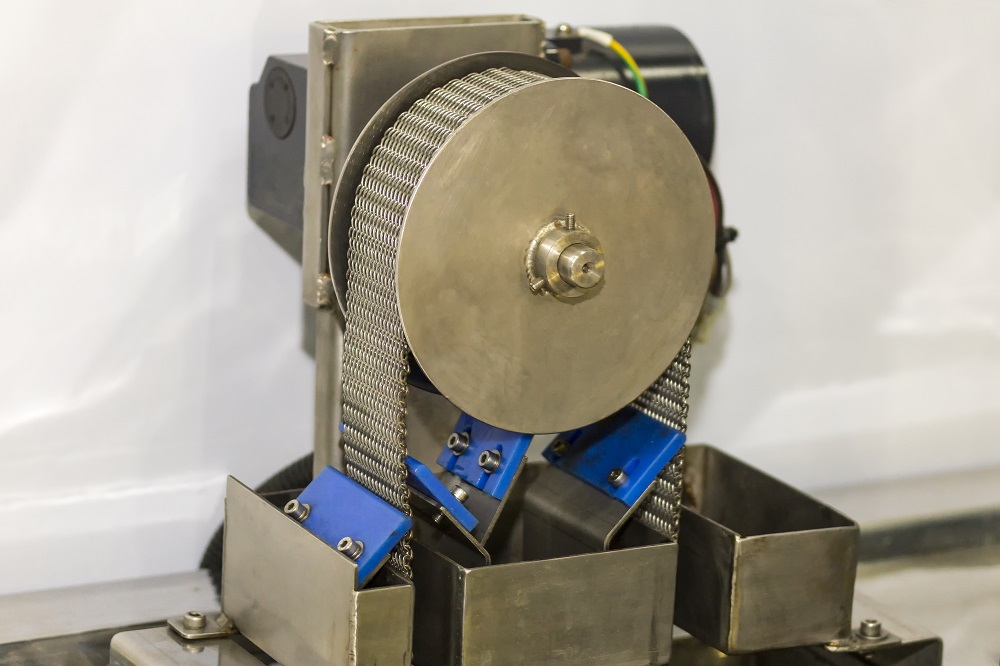

Tramp oil is unavoidable in metalworking, but it doesn’t have to slow down an operation. Here’s how to remove it from cutting fluid.

Tramp oil is unavoidable in metalworking, but it doesn’t have to slow down an operation. Here’s how to remove it from cutting fluid.

Next-generation corrosion inhibitors do more than prevent rust. Here’s what to look for in these critical-to-quality fluids.

Conventional prelubes help manufacturers overcome forming and stamping challenges. Next-generation WEDOLiT fluids accomplish that and more by also eliminating production processes.

Job shops’ tight schedules and diverse projects require very specific qualities from cutting fluids. Here’s what to look for.

The creation of TRIM® HyperSol™ 888NXT paved the way to a new category of neo-synthetic cutting fluids for the market. Here’s how it continues to improve aerospace manufacturing.

Master Fluid Solutions is a dedicated partner for metalworking facilities that want to improve their operations. Here’s what to expect during a site visit.

Demands placed on pipe and tube manufacturers are among some of the most challenging in the manufacturing sector.. That’s where the next-generation Master Fluid Solutions’ WEDOLiT™ brand forming fluids come in. Here’s what you need to know.

Coolant management can help you cut costs and improve efficiency. It can also create the foundation for business growth. Here’s how.

The decision to upgrade cutting fluid or machinery requires careful consideration and planning. Here’s how to determine which type of upgrade is appropriate.

Using the proper coolant-through system can extend the life of your tools and improve efficiency. Here’s how to choose the right one.