How to Safely Scale Up Manufacturing Operations in a Post-COVID World

COVID-19 created unprecedented disruption in the manufacturing sector. As industries recover, here’s how to safely scale up your operation.

COVID-19 created unprecedented disruption in the manufacturing sector. As industries recover, here’s how to safely scale up your operation.

The latest generation of metalworking fluids offer improvements to the entire manufacturing value chain. Here’s how this helps the environment.

Proactive scheduled machine downtime provides the perfect opportunity to improve coolant management. Here are 5 tips for optimization.

With an unstable labor market and rising material prices, production costs are out of control. Here’s how the right cutting fluid can help.

Biobased cutting fluids are redefining the industry. Here’s how TRIM® HyperSol™ 888NXT is taking sustainability to the next level.

Manufacturing is hard on workers and equipment alike. Here’s how the right cutting fluid can protect against production’s dangers.

CNC machines are the best solution for high-volume metalworking operations — but they require the right coolant delivery system. Here’s how to choose the best one.

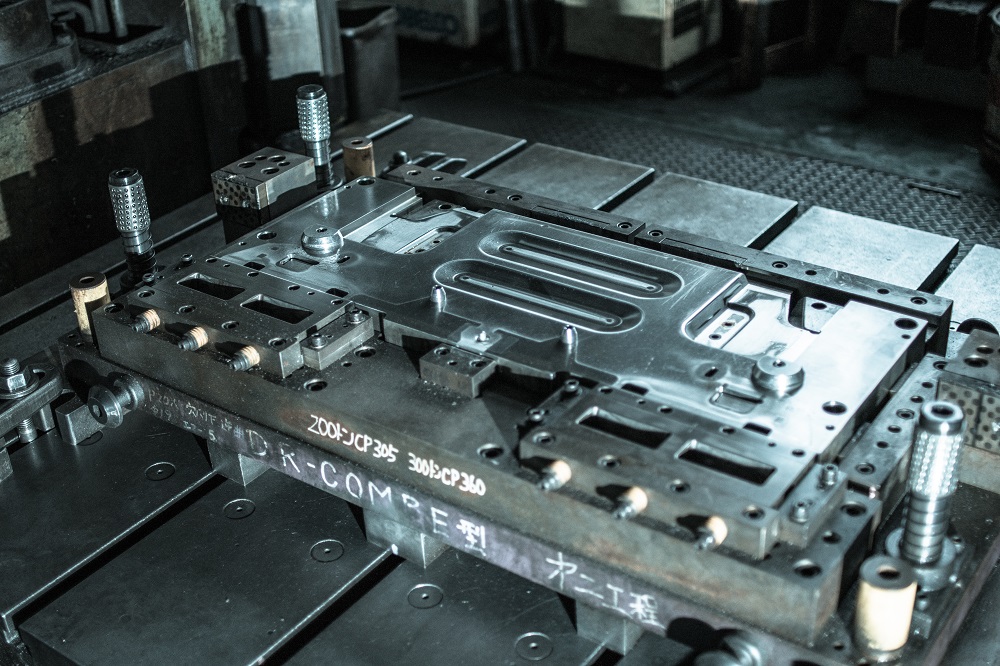

Next generation forming fluids are transforming what’s possible in stamped part production. Here’s how WEDOLiT™ forming fluids can improve manufacturability.

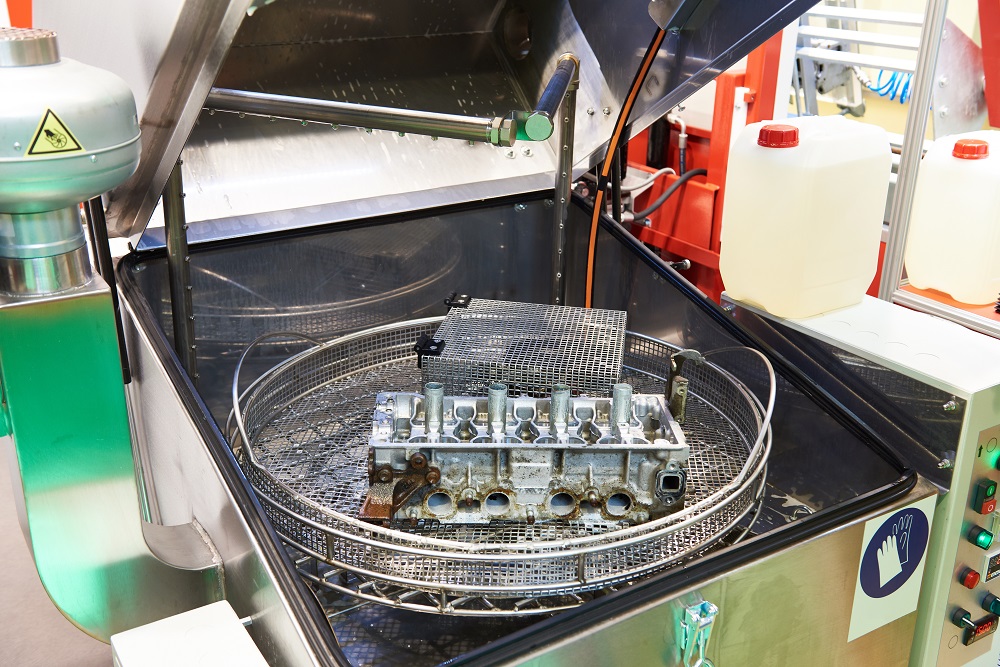

Cleaning parts is often a necessary final step in many manufacturing operations. Here’s what to look for in washing compounds and cleaning solutions.

From supply chain delays to labor market instability to thin profit margins, manufacturing faces more challenges than ever in 2021. Here’s how to overcome them.