Though demand for manufacturing has returned to pre-pandemic levels, COVID-19’s impact continues to be felt throughout the industry. In spite of the growing need for many goods, supply chains continue to lag in 2022, with international shipments delayed by months, and some materials simply unavailable. The supply chain is now presenting as many challenges for manufacturers as the labor shortage.

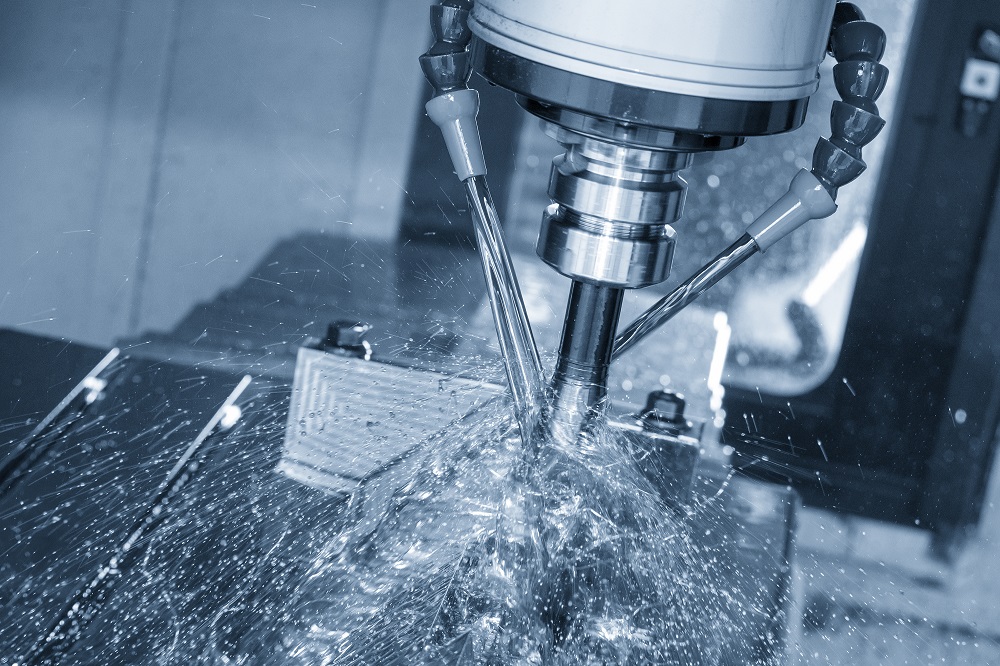

How the Right Cutting Fluid Can Improve Productivity

In lieu of switching to local suppliers or reshoring operations, manufacturers can minimize the impact of shipping delays through greater operational efficiency. It’s nearly impossible to predict timeframes for international freight right now, but if manufacturers can reduce their lead times through greater productivity, they can better meet their customers’ needs as well as protect their relationships and bottom line.

One of the best ways to improve productivity is to select the right cutting fluid. Here’s how:

Match Coolant to Material Type

In operations that are limited to just a few types of materials, choose cutting fluids that are formulated specifically for them. This can help avoid compatibility issues and optimize fluid performance for the material. In return this will minimize the amount of rework necessary for greater productivity. For example, fluids like TRIM® C390 are especially suited for aluminum, composites, stainless metals and other difficult-to-machine materials.

By contrast, in mixed machining operations, versatile cutting fluids are key. Advanced products like TRIM® MicroSol® 692XT can handle virtually any type of material and provide unparalleled cooling and lubricity, without any sacrifices.

Maximize Tool Life

Whenever machines aren’t producing new parts, manufacturers are wasting time and losing profits. One of the biggest causes of machine downtime is the need to replace worn cutting tools. Choosing the right cutting fluid can drastically extend tool life, minimize cutting tool cost and shorten time spent changing and dialing in tools. HyperSol has tripled tool life for some customers with low makeup rates, drastically reducing cutting tooling and fluid expense.

Extend Sump Life

Another major cause of machine downtime and waste is the need to clean machines and replace cutting fluid in the sump. As a true workhorse in every metalworking operation, cutting fluid is constantly collecting contaminants, including tramp oil, which can cause a buildup of sludge that reduces performance. This also creates the conditions for bacteria to grow in the sump, which actually degrades coolant and causes corrosion and unpleasant odors. Machine operators can minimize this with proper coolant management. TRIM cutting fluids have some of the longest sump lives in the industry, saving workers time, increasing production and minimizing a manufacturing operation’s waste stream.

Time has always been money in the manufacturing sector. However, in this era of ongoing supply chain issues and long shipping cycles, productivity isn’t just a way to improve the bottom line — it’s a way to get out ahead of inevitable delays and keep up with demand better than competitors. It’s important for manufacturers to control every possible aspect of their operation to avoid delays. Investing in the right cutting fluid is one of the best ways to achieve goals, regardless of what’s happening with supply chains or the labor market.

To learn more about choosing the right TRIM cutting fluid for your operation, call +1 800-537-3365 or email us at [email protected].