In today’s VUCA (volatile, uncertain, complex, and ambiguous) industry landscape, manufacturers face an increasingly disrupted supply chain — each year of the decade bringing more challenges than the one before. The recent conflict around the Suez Canal has only intensified these disruptions and their economic impact. Investing in risk mitigation strategies is more than a way to remain in the black this year; it’s now a requirement to ensure long-term success.

Companies with a wider array of product offerings are inherently more secure because they spread out risk from supply breakdown or market downturns. If you haven’t implemented a product diversification strategy in 2024, it may be time.

What is product diversification?

In manufacturing, product diversification is a strategic expansion of product offerings to enable companies to tap into new markets, lessening reliance on a single product or market segment. One of the most powerful modern examples of successful product diversification is Honda, which transformed from a modest bicycle auxilary engine manufacturer into one of the world’s largest automakers and also diversified into powersports and small engines.

Manufacturing product diversification empowers companies to increase sales and develop new revenue streams, significantly improving profit margins with potentially less overhead than other strategies. Broadening a product lineup also helps companies expand their marketshare, becoming a more versatile and resilient competitor in the global marketplace.

The Foundation for Manufacturing Product Diversification

Successful product diversification requires manufacturers to have the proper groundwork for expansion. Stakeholders need to evaluate their operation from the ground up to ensure conditions are right to actually grow the product portfolio. To conduct this evaluation:

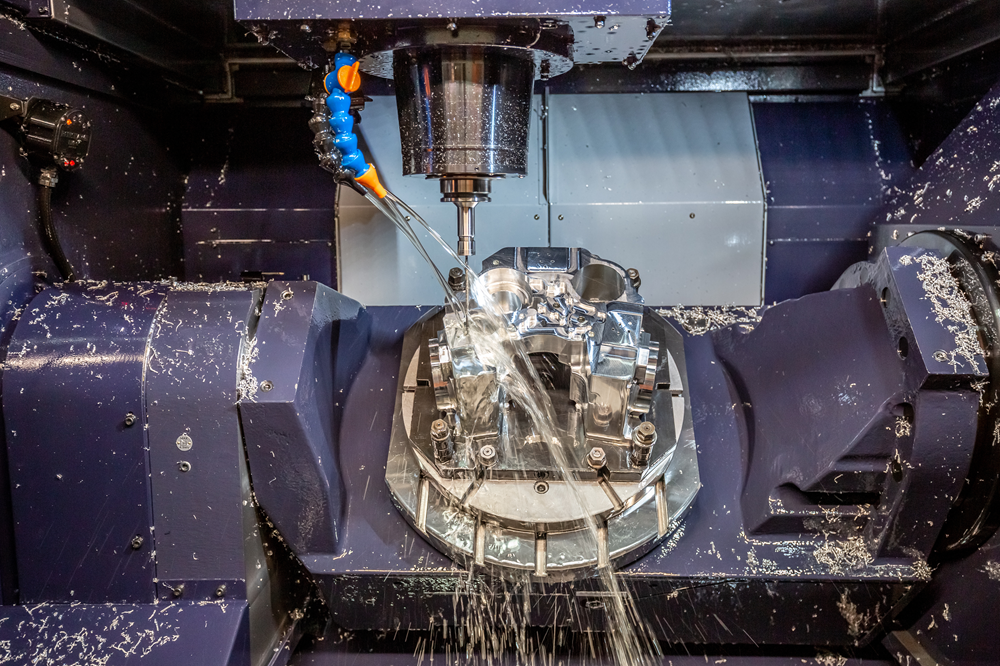

- Assess current manufacturing capabilities, including the technology and equipment you have in place for production.

- Analyze facility readiness to handle increased or different types of production demands.

- Analyze workforce skills and training needs to ensure employees can adapt to new processes or technologies.

- Audit financial records to get an accurate picture of your company’s financial health. Expanding your product portfolio requires sufficient capital to make investments without jeopardizing stability.

- Review your supply chain performance and flexibility, as diversifying products might require new suppliers or changes in logistics.

Depending on the current state of the company, laying the right foundation could involve a significant investment in infrastructure to support new product lines (including upgrading facilities and equipment), training employees with necessary skills, and even choosing more strategic cutting fluids to optimize operational efficiency.

The 2 Types of Diversification Strategies

Manufacturers typically choose one of two strategic approaches for growing their portfolio:

- Business-Level Product Diversification

The strategy of expanding into new product segments within an existing industry. For example, a wheel manufacturer could expand into other automotive parts to become a larger supplier for customers. - Company-Level Product Diversification

The strategy of expanding beyond the current industry to tackle new markets. In this case, a wheel manufacturer could expand into tool and industrial equipment manufacturing to target completely new industries.

Understanding which strategy is right for you will require further evaluation of your company.

Unearthing What Your Company Can Offer

One of the best ways to identify product diversification opportunities is to conduct a SWOT analysis — an acronym that stands for strength, weakness, opportunity, and threats. By identifying strengths, manufacturers can better understand existing capabilities and resources that are conducive to diversification. Acknowledging weaknesses allows them to spot potential gaps or deficiencies that need to be addressed before expanding product offerings. Opportunities provide insight into potential markets that a company is ready to capitalize upon. When you analyze opportunities, look at:

- Customer Feedback

Existing customers can provide direct insights into what additional products or features they need. - Internal Capabilities

Identify ways to leverage or expand existing capabilities, resources, technologies, manufacturing processes, supply chain logistics, and employee skills to create new products. - Industry Trends

Monitor sustainability, digital transformation, or shifts in regulatory landscapes for insight into new areas for product expansion. - Competitors

Identify gaps in the market that your competitors may not be addressing effectively for insight into potential product development areas. - Sales Data

Study your sales performance KPIs and customer behavior to spot potential needs your current product portfolio fails to meet.

After assessing all of these opportunities, perform a threat assessment to better understand external challenges from competition or economic conditions.

Beyond the Risks of a Narrow Product Focus

In today’s rapidly evolving market landscape, manufacturers that fail to invest in product diversification strategies risk losing their competitive edge. Stagnation in this environment is the fastest way to fall prey to future economic downturns or supply chain disruptions. But fear of revenue loss doesn’t have to be the only driving force behind portfolio expansion.

Product diversification can also play a crucial role in preventing factory downtime — a key performance metric no matter what’s happening in the market. Broadening your range of offerings ensures continuous production cycles, with operations pivoting between products based on demand fluctuations. Of course, secure foundations are key to all of this.

Truly succeeding at product diversification requires high-quality supplier partnerships that can scale quickly with the demands of your operation. From metalworking machinery to waste disposal managers to cutting fluid suppliers, you’ll need to partner with vendors as dedicated to growth and innovation as you are.