Electric vehicle (EV) production is the next great frontier in U.S. manufacturing, with opportunities in a variety of sectors for those willing to take the leap. The U.S. government has made significant investments in the production and domestication of EVs, with a total of $245 billion of federal investments dedicated to EV manufacturing and infrastructure.

This market boom presents U.S. manufacturers with two options: Adapt or be left behind. For those willing to take on EV production, here’s a breakdown of the top opportunities, challenges, and solutions that await.

Top EV Production Opportunities for Manufacturers

In the emerging EV industry, there are a number of opportunities for manufacturers to take advantage of:

Batteries

With the introduction of the Infrastructure Investment and Jobs Act and the Inflation Reduction Act, U.S. manufacturers will receive approximately $83 billion in loans, tax credits, and grants dedicated to U.S. battery manufacturing.

For metalworkers, opportunities in the battery sector lie mainly in the forming of battery compartments. Metalworkers likely already have the tools and materials to create these compartments. So, by shifting their processes, they will take advantage of an entirely new sector. These compartments present a challenge because of the specifications they require to optimize both strength and weight. Battery compartments must be

- Lightweight

- Durable

- Able to support battery and component weight

- Resistant against heat and corrosion while protecting EV batteries

These design challenges will push manufacturers to update their processes, materials, and throughput capacity, but will also present an opportunity for those who choose to adapt.

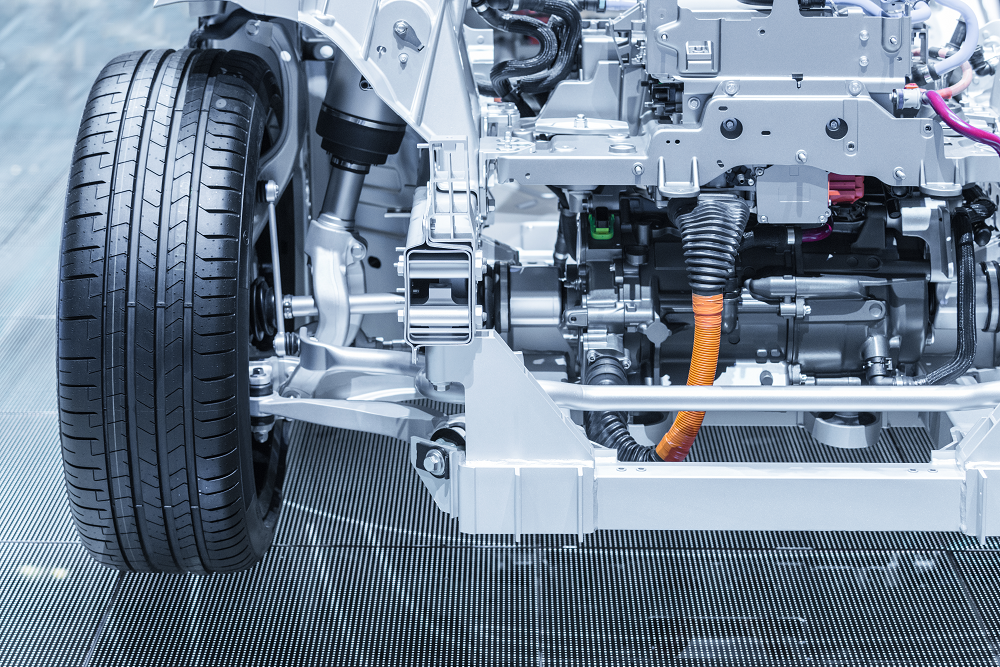

Existing Parts

While many EV components vary from those of their internal combustion engine (ICE) counterparts, these vehicles still require automotive staples like suspension, steering, and interior elements. However, many of these parts — such as wheels, drivetrains, motors, and frames — may be designed or manufactured differently, with a focus on higher strength materials or more aerodynamic design.

Manufacturers also face the challenge of creating parts that can support the weight requirements of EV batteries and components. Parts not only need to be stronger, but must adapt to new challenges such as insulating from heat and cold, being corrosive resistant, and maintaining speed and efficiency — while reducing weight as much as possible.

Common EV Challenges and How to Overcome Them

Although the EV market presents manufacturers with the potential to increase their revenue, there are also many challenges that may deter some operators from making the switch:

- Steep competition: Most auto manufacturers are looking to get into manufacturing for EVs. To stay ahead of the competition, take cues from industry experts and leaders, be proactive, and consider your constraints before making significant decisions.

- Adjusting operations: To create EV-specific parts, you may need to adjust your production processes, such as forming, cutting, and stamping. Identify which elements will remain the same and focus your efforts on adapting to the most significant changes as necessary.

- Supply chain constraints: The shift to EV parts production will likely require new materials, such as advanced high-strength steel. This means finding new suppliers and competing for availability. Diversify your supply chain and choose suppliers you trust to protect yourself from potential roadblocks.

Get ready for the EV revolution with Master Fluid Solutions

When making the switch to EV production, you need the right tools for the job. Master Fluid Solutions has a variety of next generation fluids for forming, stamping, and machining to keep your operations running smoothly.

Forming oils like WEDOLiT® N 22-4 deep-draw high-strength sheet metal, which is key for the production of battery compartments. Master Fluid Solutions is also ready to help adapt your existing parts productions to handle new material requirements with our line of TRIM® cutting fluids such as TRIM MicroSol® 692XT and TRIM E715.

To learn more about how Master Fluid Solutions can help your production adapt, contact us today.