For more than 70 years, Master Fluid Solutions has been a leader in cutting fluid technology, driving progress throughout the manufacturing sector with the TRIM® and Master STAGES™ product catalogs. The company sought to add manufacturing capability and expand further in the forming and stamping market, and looked for a brand that offered as much innovation and quality as TRIM. This culminated in the 2019 acquisition of Germany-based Wilhelm Dietz GmbH & Co. KG, and their WEDOLiT™ product line.

WEDOLiT is an industry-leading collection of metal-forming fluids, corrosion inhibitors, and specialized lubricants developed with more than 80 years of research and innovation. Now under Master Fluid Solutions’ ownership, WEDOLiT continues to raise the bar in manufacturing around the world.

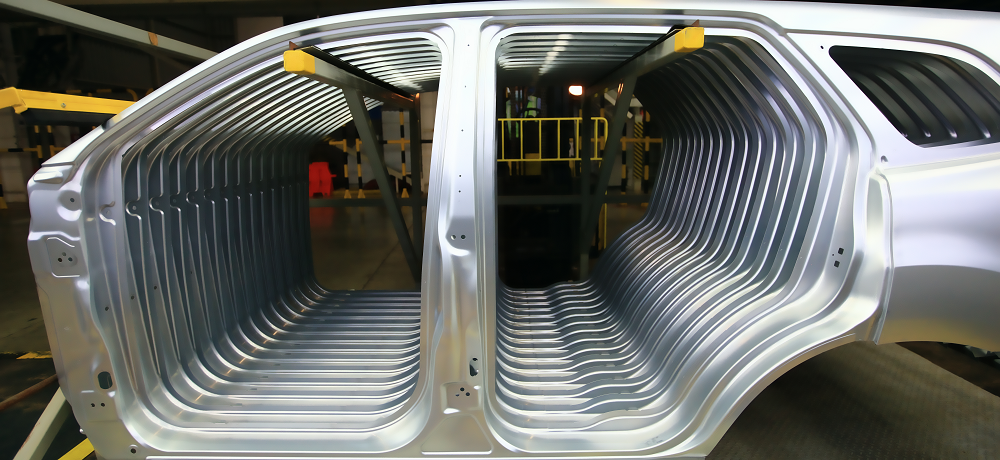

Over that time, the WEDOLiT line has enabled some major breakthroughs for customers in every manufacturing sector, including tube and pipe manufacturing, automotive, defense, energy, and more. Here are the four biggest breakthroughs the product line has helped customers achieve:

1. High Quality Corrosion Protection

One customer, an automotive parts manufacturer, suffered frequent rust issues due to inadequate corrosion protection from their current rust preventative products, especially during long international transport and as a result of conditions at interim storage facilities. During a product trial of WEDOLiT™ AN 7210, a leading edge corrosion inhibitor designed especially for steel, the customer completely eliminated corrosion from transport and storage.

Another customer, a mechanical engineering plant that creates large steel parts for industrial concrete products, has gone more than 20 years without reports of corrosion since switching to WEDOLiT AS 2603. Over that time, they have tested more than 42 competitor products but have yet to find anything that performs better than WEDOLiT.

2. Massive Reductions in Fluid Consumption

Thailand has emerged as one of the biggest manufacturing hubs for auto and motorcycle parts in Southeast Asia. One customer, a leader in this market, struggled to contain their operating costs, stemming from issues with the quality of their drawing fluids. Their previous solution required high concentrations, in addition to leaving a sticky residue on parts. The company switched to WEDOLiT FW 7652, a speciality fluid used in pipe and metal forming. The new product was so efficient that the customer reduced fluid consumption by as much as 42%.

3. Higher Productivity

One customer, a global steel tube manufacturer for the energy and automotive sectors, struggled to find an efficient dewatering product — which lowered their productivity. The customer signed up for a trial of WEDOLiT AS 1012, an advanced dewatering fluid that displaces both water and emulsions from metal surfaces almost instantly.

As a result, the company reduced their dewatering time from 10 seconds to less than five, allowing them to double throughput of their immersion baths. What’s more, they were able to increase the length of their short-term corrosion protection to more than three weeks.

4. Consolidation of Process Fluids

Another customer was able to replace every lubricant, coolant, and corrosion inhibitor used throughout their 18-step production process with just one WEDOLiT fluid. The company, a German munitions manufacturer, previously used almost a dozen fluids throughout their cartridge drawing process, drastically increasing supply costs as well as production times. After switching to WEDOLiT FW 9200, the advanced forming lubricant replaced every other fluid they used in their operation, drastically cutting costs and simplifying workflow.

Like all Master Fluid Solutions’ products, WEDOLiT can significantly improve productivity, minimize waste, reduce fluid consumption and operating costs, and increase profitability. WEDOLiT products often have multiple benefits, so many customers have switched to WEDOLiT to solve a specific problem, only to reap additional benefits in other areas as well. To learn more about WEDOLiT, or to schedule a trial at your facility, call +1 800-537-3365 or email us at info@masterfluids.com.