Coolant maintenance as we know it was pioneered by Master Fluid Solutions® in 1971. Before conservation became a major talking point, founder Clyde A Sluhan, his son Bill, and engineer Jay Threadgill developed the first coolant recycling system, which purified cutting fluids of tramp oil, chips, and other contaminants so it could maintain optimal performance and last longer in the sump and minimize waste. The product was so effective that customers were able to lower their fluid purchase volume. This quickly caught the attention of everyone in the metalworking industry and became standard.

Now, Master Fluid Solutions offers an entire line of XYBEX filters, mixers, sump suckers, recyclers, and centrifuges to handle every coolant maintenance need. In addition, Master’s technical experts work regularly with customers to improve their coolant management protocols. Making sure fluids perform optimally and last as long as possible is key to maintaining the overall profitability of a shop. Making even small changes to how you treat your cutting fluid can lead to major improvements in profit and productivity and minimize environmental impact. Here’s how:

Less Coolant Waste

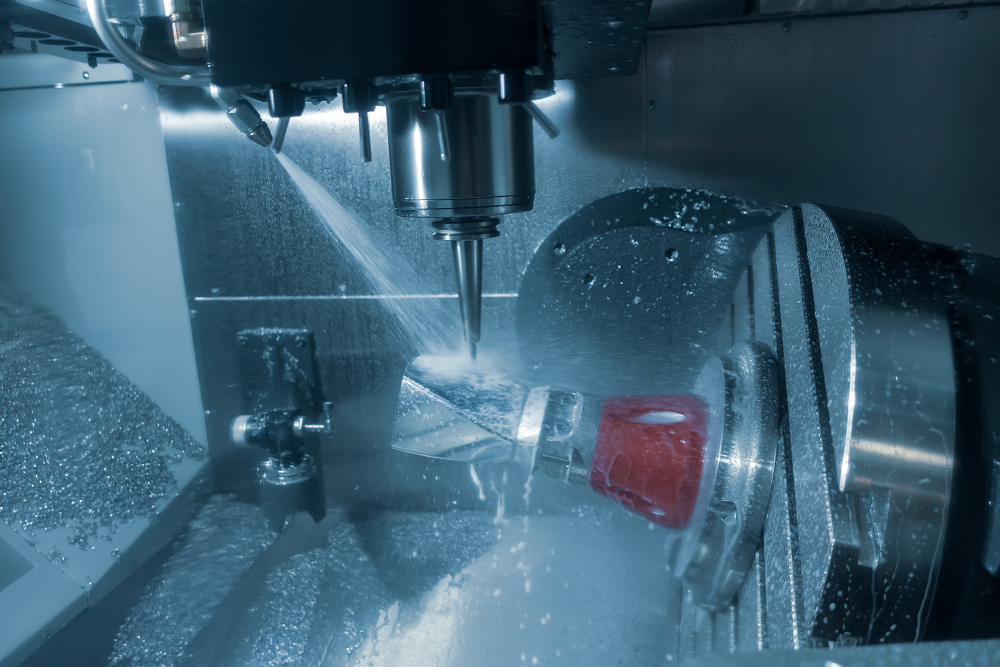

Cutting fluid is a true workhorse in any metalworking operation, responsible for keeping cutting tools lubricated and cool and flushing away chips from the cutting zone. Keeping metalworking fluid clean can not only help it perform its job better, but also greatly increase sump life, leading to less frequent clean outs and downtime.

On average, coolant makes up less than 1% of any operation’s total budget, but cost savings from preventing waste can significantly add up over time. Minimizing clean outs also allows workers to focus more on machining, improving their productivity, and enhancing profits.

Longer Tool Life

One of the biggest impacts of proper coolant management is on tool life. When fluid gets dirty and contaminated, tools suffer from accelerated wear and need more frequent replacement. It can also cause other issues, like built up edge corrosion and bacteria growth. Short tool life can be one of the biggest sources of additional costs and material waste and can balloon already-tight budgets, but proper coolant maintenance can keep them performing better, longer.

Less Machine Downtime

No one likes cleaning coolant sumps, and a lot of shops let their coolant get so dirty that replacement is unavoidable. This doesn’t just contribute to waste — it can also cause major problems with an operation. The goal should be to put in effort to keep coolant at the proper concentration and minimize contamination. If cutting fluid gets too contaminated with tramp oil, particles, and chips, it can create sludge that can harbor bacteria or damage coolant through systems, plug filters, and even tools.

The time workers spend cleaning machines and replacing coolant prematurely or dealing with corrosion and tool life issues can reduce throughput. Also, the corrosion can damage equipment enough to necessitate repairs or replacement, further driving up costs and wasting valuable time.

Better Work Environment

Every operator prefers to work in clean and maintained coolant over dirty coolant. Bacteria love to grow in dirty coolant, and, unfortunately, this can create some major challenges for workers. For starters, it produces unpleasant odors and decreases air quality. Such a negative environment can harm morale and reduce productivity. Dirty coolant will also inevitably end up on worker’s hands, and the bacteria and fines can cause dermatitis that affects workers, can lower quality of life, and further reduce productivity. Bacteria will also begin to break down the coolant emulsion and its properties.

Proper coolant maintenance is one of the best ways to reduce operating costs and improve productivity. Want to schedule a site visit to learn more about cutting fluid management? Call +1 800-537-3365 or email us at [email protected].